Common Diesel Engine Issues and How to Beat Them

Did you know that nearly 65% of diesel engine breakdowns are avoidable with the right know-how and regular care? That’s particularly important for diesel truck owners in Columbia, SC, where local climate and driving conditions put unique strains on your engine. Whether you drive for work, haul heavy loads, or rely on your diesel truck for daily commutes, understanding and preventing common diesel engine issues can save you money and keep you on the road—safely and reliably.

Diesel Engine Reliability: A Surprising Statistic on Common Diesel Engine Issues

When it comes to diesel engine reliability, the numbers might raise your eyebrows. Despite their reputation for toughness, common diesel engine issues are more frequent than many truck owners realize—especially in demanding regions like Columbia, SC. Studies show more than half of all reported diesel engine failures stem from a handful of specific, preventable problems. This means many breakdowns are avoidable with proper attention and timely intervention. In an area where temperature swings, humidity, and urban stop-and-go traffic test your engine daily, proactive care is even more critical.

It isn’t just the rural workhorse or off-road rig—diesel engines in delivery vehicles, construction trucks, and personal pickups all encounter issues unique to their design and use. For Columbia drivers, understanding the root causes of these engine issues—like fuel system contamination and failing glow plugs—can help you spot warning signs early and dodge costly downtime.

“Recent studies reveal that nearly 65% of diesel engine breakdowns are due to preventable issues—many specific to diesel truck owners in Columbia, SC.”

What You’ll Learn in This Guide to Common Diesel Engine Issues

- The most common diesel engine issues faced by owners

- Key differences between diesel engines and other engine types

- How to detect, prevent, and address common diesel engine problems

- Expert maintenance tips tailored for diesel trucks in Columbia, SC

Understanding Diesel Engines: Anatomy and Operation

Diesel Engine Fundamentals – What Makes Diesel Engines Unique?

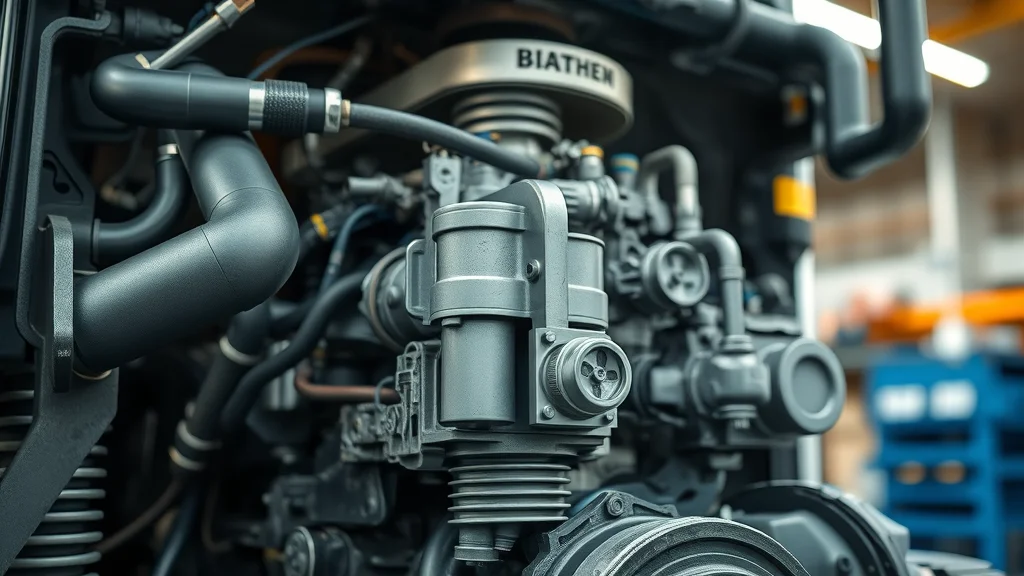

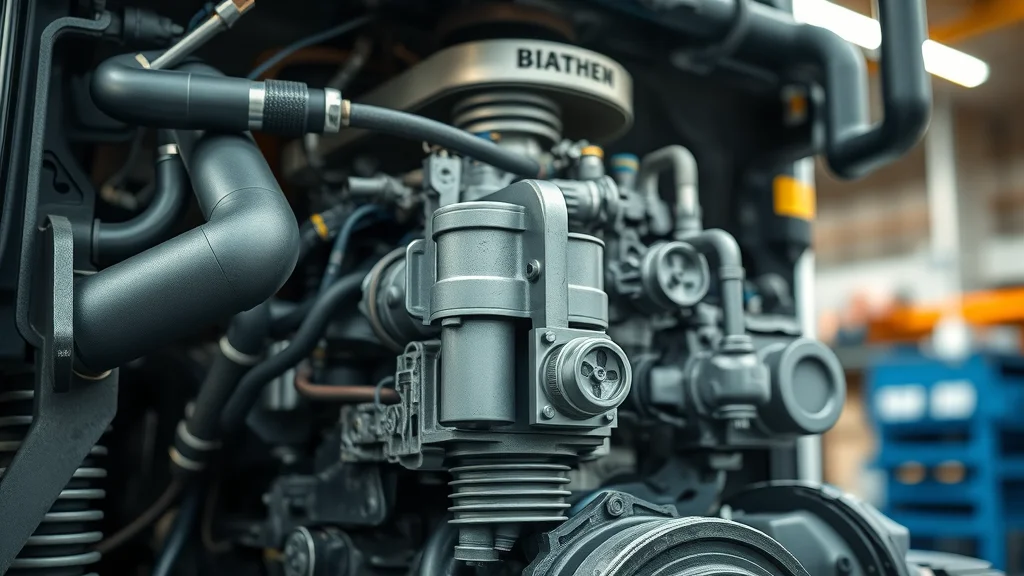

Diesel engines power some of the hardest-working trucks on Columbia, SC’s roads, but how exactly do they differ from gasoline engines? Unlike gas engines that rely on spark plugs to ignite fuel, diesel engines use high compression to raise the temperature of air in the cylinder, igniting the injected diesel fuel without a spark. This design delivers superior torque and efficiency, making diesel engines the backbone of trucking and heavy-duty work.

The trade-off for this power and longevity, though, is a need for precision in fuel delivery and air management. Components such as fuel injectors, glow plugs, water separators, and high-capacity fuel pumps work in unison to supply clean, pressurized diesel fuel. Modern diesel engines also feature advanced air filtration and emission controls. If any component develops problems, it often leads directly to familiar diesel engine issues—like rough idling, hard starts, or sudden power loss. Understanding the unique anatomy of your engine is the first step to identifying and preventing common diesel engine issues that can crop up over time.

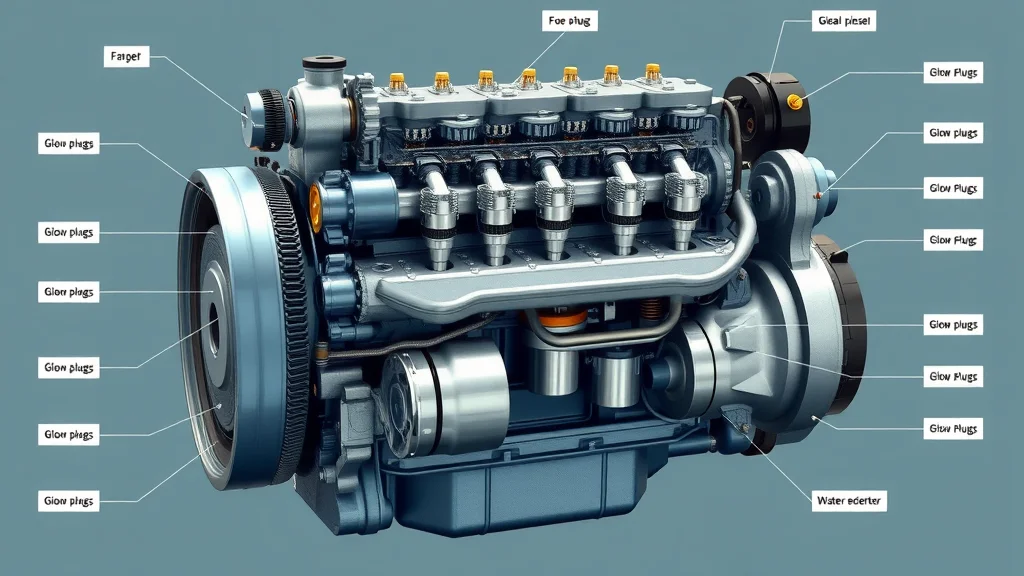

Common Diesel Engine Components: Fuel Injectors, Glow Plugs, and Water Separators

To keep your diesel engine running smoothly, it helps to recognize the vital parts most commonly associated with engine issues:

- Fuel Injectors: These precision components spray atomized diesel fuel directly into the combustion chamber. When fuel injectors clog or wear out, they cause rough running, poor fuel consumption, and can even lead to engine misfire or failure.

- Glow Plugs: Unlike spark plugs, glow plugs heat the combustion chamber for cold starts. Failing glow plugs are a leading source of hard starting and excessive white smoke, especially noticeable on chilly Columbia mornings.

- Water Separator: Diesel fuel systems include a separator to remove water and debris—critical for engine health. Ignoring maintenance of this part leads to fuel system issues, hesitations, and potentially severe engine damage.

Watch: Video Demonstration: Visual Guide to Diesel Engine Component Functions (See your mechanic or trusted video resources for a comprehensive visual walkthrough. )

Staying on top of these essential components is key to preventing breakdowns. For a deeper dive into professional maintenance and repair solutions tailored to diesel trucks, explore the diesel truck repair and service options available in Columbia, SC—these services can help you address issues before they become costly problems.

Common Diesel Engine Issues Seen in Columbia, SC

Identifying the Most Frequent Diesel Engine Issues

Diesel truck owners in Columbia, SC report a set of recurring engine issues with surprising frequency. If you’ve experienced any of the following, you’re not alone—and early recognition is key:

- Faulty fuel injector and fuel injectors

- Glow plug failure

- Diesel fuel contamination and water separator blockages

- Engine overheating and cooling system malfunctions

- Starting problems and stalling

Symptoms like rough idling, power loss, excessive exhaust smoke, and hard cold starts often point to these core problems. The underlying causes may be as simple as a worn glow plug or as complicated as water in your diesel fuel—especially if routine maintenance is skipped. Columbia’s warm summers and humid conditions can accelerate fuel system issues and cooling system failures unless your truck gets the regular care it needs.

Table: Quick Reference to Common Diesel Engine Issues

| Issue | Symptom | Typical Cause | Fix |

|---|---|---|---|

| Faulty Fuel Injector | Rough running, smoke | Clogged/failed injector | Clean or replace fuel injector |

| Glow Plug Failure | Hard cold starts | Worn-out glow plugs | Replace glow plugs |

| Fuel Contamination | Power loss, misfire | Water/debris in diesel fuel | Drain tank, replace filters, use additive |

| Overheating | Steam, high temp gauge | Cooling system issue | Check coolant, inspect radiator, fans |

| Water Separator Blockage | Engine hesitation | Neglected maintenance | Drain and replace separator |

Diagnosing and Solving Fuel Injector Problems: A Common Diesel Engine Issue

Warning Signs of Fuel Injector Issues

Fuel injector problems are one of the most common diesel engine issues, resulting in symptoms like rough idling, loss of power, excessive dark smoke, and increased fuel consumption. Columbia truck owners often notice these warning signs when their engine hesitates, sputters, or struggles under load. A faulty fuel injector can be caused by poor fuel quality, neglecting the fuel filter change, or contamination entering the fuel system through bad fuel lines or neglected maintenance routines. Early detection can make all the difference—in many cases, prompt injector cleaning or replacement restores engine performance and fuel economy, avoiding further engine issues.

If your diesel engine is showing any of these symptoms, don’t ignore the problem. Persistent rough running, uneven acceleration, or visible leaks around fuel injectors often signal that immediate attention is needed. Columbia’s variable climate can cause moisture buildup in diesel fuel, multiplying the risk of internal corrosion or injector blockage; regular inspection and cleaning keep these parts working efficiently and extend overall engine life.

Expert Insight: Why Fuel Injectors Are Vital for Diesel Engines

Properly functioning fuel injectors ensure that your diesel engine receives precisely metered, atomized fuel—creating the trademark torque and efficiency diesel is known for. When injectors clog, the spray pattern distorts, causing incomplete combustion, excessive smoke, and detectable drops in performance. Premium diesel fuel and scheduled filter changes are essential, especially for high-mileage diesel trucks seen around Columbia, SC. Expert technicians recommend routine injection system inspections and sticking to service intervals outlined in your truck’s maintenance guide.

“Consistently clogged fuel injectors are a leading contributor to common diesel engine issues—regular cleaning and premium fuel are key.”

Step-by-Step: How to Fix Fuel Injector Problems in Diesel Engines

Addressing fuel injector problems starts with diagnosing the issue using modern diagnostic tools. After pinpointing the bad injector, the next steps include:

- Shut down the engine and allow it to cool.

- Remove the necessary engine covers and identify the faulty injector.

- Gently disconnect the injector electrical plug and carefully extract the suspected injector using proper tools.

- Clean the injector with specialized solvent and ultrasonic cleaner, or replace with a new OE-quality injector if cleaning doesn’t resolve the issue.

- Reinstall and torque to manufacturer specs, reconnect wires, then prime the fuel system and restart the engine.

Always follow the manufacturer’s instructions and consider hiring a certified diesel technician if you’re not confident with this process. High-pressure fuel systems require trained handling, and mistakes can create dangerous leaks or long-term engine damage.

Watch: Video Tutorial: Fuel Injector Cleaning and Replacement for Diesel Truck Owners (Check trusted mechanic channels for step-by-step visuals. )

Troubleshooting Glow Plug and Starting Issues: Avoiding Costly Engine Issues

Common Symptoms of Glow Plug Failure

Glow plug failure is a top culprit behind cold starting problems and uneven idling for diesel engines in Columbia, SC. Truck owners will often notice:

- Longer engine crank times, especially on chilly mornings

- Heavy white or grey exhaust smoke after starting

- Unstable idle or engine misfire immediately after starting

Repeated failed starts or white smoke should never be ignored. In Columbia’s climate, even moderate winter chills can highlight weak or dead glow plugs, hampering your engine’s ability to ignite fuel efficiently. Since glow plugs are a wear item, routine glow plug testing and preemptive replacement keep your truck ready for all seasonal changes.

It’s also wise to inspect for related issues such as faulty relays or wiring problems if replacing the plug doesn’t fix the problem. Keeping a set of quality spare glow plugs in your maintenance kit can be a lifesaver during unexpected cold snaps or early morning starts.

How to Replace Glow Plugs to Address Common Diesel Engine Issues

- Glow plug testing techniques: Use a multimeter or specialized glow plug tester to check the resistance of each plug. Any reading outside the recommended range means the plug should be changed.

- When to replace glow plugs: If your diesel engine shows repeated hard starts or fails glow plug resistance tests, replace all plugs in the set to maintain balanced starting power.

- How to prevent glow plug failure in Columbia’s climate: Stick to your truck’s maintenance schedule, use quality diesel fuel, and protect electrical connections from humidity and corrosion with regular inspections.

After confirming glow plug failure, remove each glow plug gently, replace it with a new unit, and torque to specifications. Always start with a clean engine bay to avoid debris falling into the cylinder head. Completing the job ensures your diesel engine’s starting system remains reliable—no matter what Columbia’s weather throws your way.

The Role of Glow Plugs in Diesel Engine Starting Performance

Glow plugs are critical for reliable diesel engine starts, especially when temperatures dip. When functioning correctly, glow plugs preheat combustion chambers to promote smoother ignition and minimize white smoke. If neglected, faulty glow plugs contribute not only to starting issues but also to added stress on fuel injectors and batteries. Truck owners in Columbia, SC should prioritize periodic glow plug testing and swift replacement at the first signs of wear, ensuring their diesel engines stay dependable regardless of the season.

For best performance, combine glow plug maintenance with regular fuel and air filter checks, as these systems often support one another in ensuring complete ignition and smooth engine running. When these components work together seamlessly, most common diesel engine issues become preventable inconveniences rather than costly headaches.

Recognizing and Preventing Fuel System and Diesel Fuel Problems

Diesel Fuel Contamination: A Silent Saboteur

Fuel system contamination—especially water and debris in your diesel fuel—is a silent but scary culprit behind many common diesel engine issues in Columbia, SC. Contaminated diesel can clog the fuel filter and injectors, reduce engine performance, cause rough idling and misfires, and in worst cases, lead to major engine failure. Water often enters the system through condensation, bad storage, or inferior fuel from unreliable pumps. Once water or particulates make their way into fuel lines or the injection system, they accelerate corrosion and clogging, often going unnoticed until symptoms become severe.

Regularly checking the fuel water separator and using premium, quality diesel fuel can minimize problems. If you notice unexpected drops in power, erratic idling, or stalling, don’t delay inspection—these are often early warnings of deeper fuel system contamination issues threatening your engine’s longevity. Columbia’s humidity and rain fluctuations can worsen the likelihood of condensation forming in partially filled tanks, underlining the need for vigilance and regular maintenance.

Maintaining Your Diesel Fuel System: Filters, Water Separators, and Best Practices

The health of your diesel engine hinges on a clean, efficiently operating fuel system. To prevent the most common diesel engine issues, keep up with recommended fuel filter changes (often every 10,000–20,000 miles), and inspect your water separator at every service interval. Water separators are easily drained—a simple but crucial habit that spares your injectors and pumps from contaminated fuel loads.

Best practices also include vigilantly monitoring your tank for fuel leaks, fuel line damage, and regular use of diesel additives to keep internal parts corrosion-free. When inspecting the system, replace any damaged fuel lines, and flush the system if contamination is detected. Even modern diesel engines benefit greatly from old-fashioned attention to detail at every fuel stop and scheduled maintenance. Small investments of time yield long-term reliability and fewer surprise repairs.

Table: Common Fuel System Issues and Solutions for Diesel Engines

| Fuel System Issue | Cause | Solution |

|---|---|---|

| Water in Diesel Fuel | Bad fuel, condensation | Drain separator, replace filter |

| Clogged Fuel Filter | Poor maintenance, contaminated fuel | Replace filter, flush system |

| Leaky Fuel Lines | Age, road damage, vibration | Inspect and replace lines |

Engine Cooling System Problems: Preventing Diesel Engine Overheating

Common Reasons Diesel Engines Overheat

Overheating is a frequent cause of diesel engine issues—especially in South Carolina’s sweltering summers. The most common reasons for diesel truck overheating include low coolant levels, neglected coolant leaks, faulty thermostats, damaged or clogged radiators, and failed water pumps. Even a small loss of coolant or an air pocket can rapidly cause temperature spikes, resulting in steam, burning smells, or a bright red engine temp gauge. Other culprits, such as collapsed radiator hoses, stuck cooling fans, and blocked heater cores, add risk to older trucks or those with lengthy service intervals.

Paying attention to coolant level, fan operation, and visible coolant leaks will catch many issues early. Many Columbia drivers mistakenly attribute overheating solely to hot weather, but mechanical wear and low coolant levels are equally dangerous. Addressing cooling system issues promptly not only prevents engine damage but also preserves your truck’s vital components, such as the cylinder head and exhaust system.

Steps for Maintaining Your Diesel Engine’s Cooling System

- Check coolant levels regularly

- Flush radiator and cooling system on schedule

- Watch for coolant leaks and bad thermostats

Consistent attention pays off: a topped-off and clean cooling system enables modern diesel engines to run efficiently under all types of loads. Use only manufacturer-approved coolant mixtures to avoid deposit buildups, and have your system pressure-tested annually or whenever signs of engine issues arise. Paired with vigilant inspection of hoses and the water pump, good cooling system habits keep South Carolina’s climate from sidelining your diesel truck unexpectedly.

Hard Starting and Stalling: Common Diesel Engine Issues in Cold and Warm Weather

Why Common Diesel Engines Struggle to Start

Hard starting is a classic sign of unresolved diesel engine issues. Common causes include weak glow plugs, a low or dead battery (especially after cold snaps), fuel system air leaks, and contaminated fuel. Many Columbia, SC owners are surprised to learn that cold weather isn’t the only reason for hard starts—humid summers can spark condensation within the fuel tank, exacerbating injector and filter problems. Battery age, corroded connections, and starter motor wear also make diesel engines more difficult to crank over.

Other factors, such as air entering the fuel system through loose or cracked fuel lines, can also starve the injectors during start-up, forcing the engine to crank longer and adding stress to the starting system. Timely glow plug checks, quality fuel, and inspecting battery condition alongside terminal cleaning, can prevent most hard starting issues encountered locally.

Troubleshooting Frequent Stalling in Diesel Engines

Engine stalling, whether idling at a light or under acceleration, is both frustrating and potentially hazardous. For many diesel truck owners in Columbia, stalling is typically traced back to fuel system neglect—clogged fuel filters, failing fuel pumps, or debris blocking the water separator. Inconsistent fuel supply or air infiltration into the system disrupts injector timing, leading to intermittent stalling.

“Cold weather is not the only reason for starting problems—fuel system neglect and battery condition top the list for common diesel engine issues.”

Identifying the root cause often involves checking filter condition, testing fuel pressure, and inspecting for visible leaks. Occasionally, electrical issues—like cracked wiring or a weak starter relay—are the surprise culprits. Addressing these areas will restore a reliable, confident ride for your diesel.

Best Practices for Quick Starting and Reliable Operation

- Use premium, quality diesel fuel and change filters regularly

- Test and replace glow plugs at recommended intervals

- Maintain battery health with periodic inspections and terminal cleaning

- Monitor coolant and air filter condition to prevent cascading engine issues

Diesel engines, particularly those working hard in Columbia’s variable climate, benefit most from a thoughtful, proactive approach. Combining regular fuel, cooling, and air filter checks with early symptom detection is your best defense against seasonal nuisance and costly repairs down the line.

Watch: Video Guide: Diagnosing Diesel Engine Cold Start and Stalling Issues (Consult local diesel experts for platform-specific troubleshooting videos. )

Routine Maintenance Tips to Avoid Common Diesel Engine Problems

Scheduled Service Checklist for Diesel Truck Owners

- Regular oil and filter changes

- Check and replace air filters

- Inspect and clean battery terminals

- Flush cooling system as needed

- Inspect fuel system components every service interval

Adhering to a strict maintenance schedule is far and away the most effective way to steer clear of common diesel engine issues. Don’t forget secondary checks: look for oil leaks, coolant leaks, and inspect all belts and hoses. Regular visits to a trusted diesel mechanic in Columbia, SC ensure problems are identified early and fixed by professionals who understand the intricacies of modern diesel engines.

Consider keeping a maintenance log and checklist specific to your vehicle’s recommendations, and always use OEM-quality or better replacement parts. Investing in ongoing education for yourself or your drivers also returns dividends in enhanced reliability and lower cost of operation over your truck’s life cycle.

People Also Ask: Insights for Diesel Truck Owners

What is the most common problem with diesel engines?

The most common problem with diesel engines is fuel system contamination, including clogged fuel injectors and dirty filters. These issues reduce engine performance, cause misfires, and can ultimately lead to major engine failures if not addressed promptly. Regular filter changes and buying high-quality diesel fuel help minimize these risks.

What is the most unreliable diesel engine?

The early 6. 0L Powerstroke V8 diesel engine, used in mid-2000s Ford trucks, is widely regarded as one of the least reliable diesel engines. It suffers frequent injector failures, head gasket problems, and cooling system issues, earning it a notorious reputation among diesel truck owners.

What’s the worst thing for a diesel engine?

Neglecting maintenance and allowing water, dirt, or low-quality diesel fuel into the system is the worst thing for a diesel engine. Such neglect leads to corrosion, fuel system blockages, and catastrophic injector or pump damage, all of which severely impact engine reliability and lifespan.

What is the holy grail of diesel engines?

The Cummins 5. 9L inline-6 diesel engine is often called the “holy grail” of diesel engines. Its legendary reliability, robust durability, and straightforward design make it a favorite among diesel enthusiasts and truck owners alike, with many capable of reaching high mileage with minimal trouble.

FAQs About Common Diesel Engine Issues for Columbia Truck Owners

How often should I change the diesel fuel filter in my truck?

It’s recommended to change your diesel fuel filter every 10,000 to 20,000 miles, or according to the service interval suggested by your truck’s manufacturer. More frequent changes may be needed if you operate in dusty conditions or use lower-quality fuel.

Can I use standard engine oil in my diesel engine?

No, you should always use oil formulated for diesel engines. Diesel engine oils include additives specifically for soot control and lubrication under higher pressures and temperatures unique to diesel engines. Using standard oil risks insufficient protection and possible engine damage.

What signs indicate a failing glow plug?

Hard starts, excessive white smoke during cold starts, and uneven idling after engine ignition are the primary signs of a failing glow plug. If your engine is slow to crank or misfires in cooler weather, it’s wise to test the glow plugs and replace worn units promptly.

Is it safe to drive with a minor diesel engine issue?

Driving with a minor diesel engine issue may be possible for a short distance but is not recommended. Continuing to drive risks worsening the problem—potentially leading to expensive repairs, roadside breakdown, or even engine failure. Address all warning signs as soon as possible.

Key Takeaways: Preventing and Fixing Common Diesel Engine Issues

- Routine maintenance is crucial to avoid costly repairs

- Most diesel engine issues stem from fuel system neglect

- Early detection saves money and prolongs engine life

Find a Trusted Diesel Mechanic in Columbia, SC to Address Your Diesel Engine Issues Today

Don’t let common diesel engine issues slow you down or risk your livelihood. Contact a proven Columbia, SC diesel mechanic for diagnostics, maintenance, or expert repairs to keep your truck running strong, no matter the challenge.

Book your diesel service with Columbia’s trusted mechanics now at Call Road 1.

If you’re ready to take your diesel truck’s reliability to the next level, consider exploring comprehensive repair and service strategies that go beyond basic troubleshooting. The diesel truck repair and service resources at Call Road 1 offer advanced diagnostics, preventive maintenance plans, and expert advice tailored to the unique demands of Columbia, SC drivers. By partnering with specialists who understand both the technical and practical aspects of diesel ownership, you can maximize uptime, extend your engine’s lifespan, and drive with greater confidence year-round. Discover how a proactive approach to diesel care can transform your experience behind the wheel and help you stay ahead of future challenges.

Sources

- https://www.cummins.com/news/2020/common-diesel-engine-problems-and-how-fix-them – Cummins Newsroom

- https://www.napaonline.com/en/auto-care/diesel-engine-maintenance-and-common-issues – NAPA Auto Care

- https://www.dieselhub.com/maintenance/common-diesel-engine-problems.html – Diesel Hub

- https://dieselresource.com/diesel-maintenance/common-diesel-problems/ – Diesel Resource

Understanding and addressing common diesel engine issues is crucial for maintaining vehicle performance and longevity. For a comprehensive overview, consider the article “Diesel Engine Maintenance and Common Issues,” which outlines prevalent problems and offers maintenance tips. Additionally, “Common Diesel Engine Problems and How to Fix Them” provides insights into troubleshooting and resolving typical diesel engine challenges. These resources offer valuable information to help you identify and prevent potential issues, ensuring your diesel engine operates efficiently.