Diesel Engine Troubleshooting: Solve Issues Fast

Did you know that nearly 70% of breakdowns in diesel trucks are caused by just three common issues? Understanding diesel engine troubleshooting can save owners thousands each year. For Columbia, SC diesel truck owners, these facts aren’t just statistics—they’re the difference between getting back on the road fast or facing costly downtime. If your livelihood depends on the reliable performance of your diesel engine, mastering quick troubleshooting is not just helpful, it’s essential. This in-depth guide arms you with everything you need to identify, solve, and prevent diesel engine problems—so you spend more time driving and less time worrying about unexpected repairs.

“Did you know that nearly 70% of breakdowns in diesel trucks are caused by just three common issues? Understanding diesel engine troubleshooting can save owners thousands each year.”

Diesel Engine Troubleshooting: Key to Your Truck’s Reliability

When it comes to the reliability of your diesel truck, nothing is more crucial than effective diesel engine troubleshooting. Trucks in Columbia, SC face unique local challenges like humid summers and hot roads, which are notorious for accelerating wear on critical components such as glow plugs, injectors, and filters. Addressing troubleshooting early means you can avoid the high costs associated with common problems such as low oil, air leaks, and faulty injectors, while also preventing breakdowns that could leave you stranded.

Modern diesel engines are marvels of power and efficiency, but that means they also demand knowledgeable care. Diesel engine troubleshooting gives you the upper hand: learning to recognize the early warning signs—like sudden changes in fuel consumption, unexplained engine fault codes, or excessive smoke—can prevent a small issue from ballooning into a full-blown engine failure. By maintaining regular visual inspections and using diagnostic tools, Columbia, SC truck owners can protect their investments and ensure their trucks deliver peak performance year-round. Prioritizing a proactive approach to engine troubleshooting not only reduces downtime but builds truck reliability for every mile ahead.

For those looking to go beyond troubleshooting and ensure their truck is always road-ready, exploring comprehensive diesel truck repair and service options can provide added peace of mind and long-term reliability.

What You’ll Learn About Diesel Engine Troubleshooting

- How to identify and solve frequent diesel engine troubleshooting issues

- Tips to prevent future diesel engine problems in your truck

- Step-by-step diesel engine troubleshooting guides

- Expert quotes and advice for Columbia, SC truck owners

Understanding Diesel Engines: The Core Principles

How Diesel Engines Work: Power, Efficiency, and Reliability

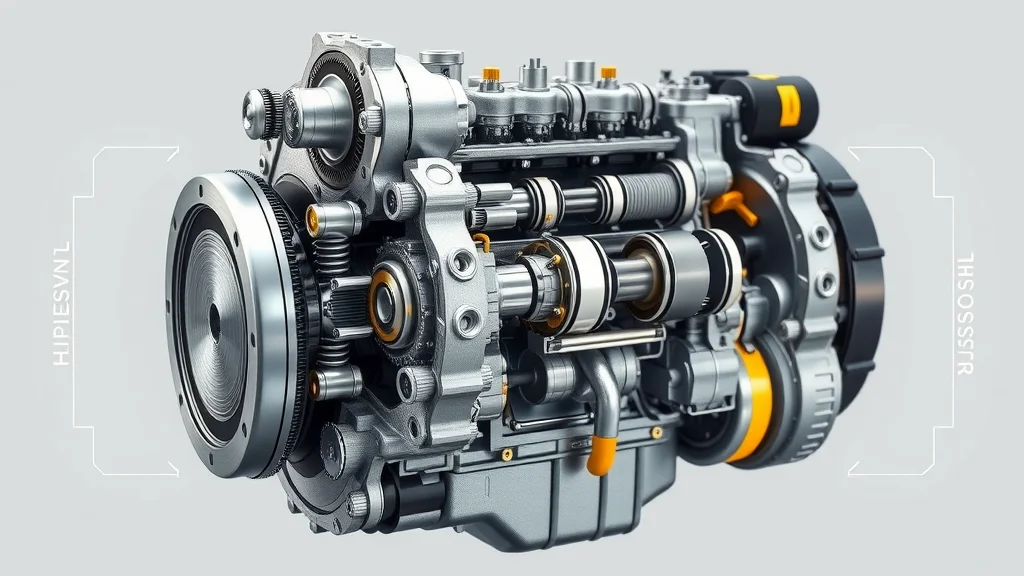

Diesel engines have become the backbone of trucking, renowned for their unparalleled power, efficiency, and durability. Unlike gasoline engines, diesel engines ignite fuel through the heat of compression, which leads to higher energy efficiency and torque output—key for heavy-duty hauling in and around Columbia, SC. The diesel engine troubleshooting process starts with understanding these core differences. Diesel engines leverage high pressure fuel injection, robust construction, and intricate control modules to withstand intense workloads across thousands of miles. This strong foundation explains their reliability—but when common problems do occur, these very features can also make troubleshooting more complex. Recognizing how systems such as the electronic control module, glow plugs, and injector pumps interact will help lay the groundwork for any repair or diagnostic decision.

In addition to sheer mechanical strength, modern diesel engines depend on advanced sensors and high-precision fuel delivery. Components like piston rings, air filters, and fuel injectors each play a unique role—and any failure in these systems (from valve seals to a coolant leak) can produce a cascade effect throughout the truck. By understanding the interrelated mechanics and electronics at play, you’ll approach diesel engine troubleshooting as a strategic process rather than guesswork, drastically increasing your chances of a swift resolution.

Key Diesel Engines Components Every Owner Should Know

Successful diesel engine troubleshooting requires knowing your engine’s vital components inside and out. Chief among them are the fuel injectors, responsible for delivering precise sprays of diesel into the high-compression cylinders. Any issues here, such as clogged injectors or delivery problems, can result in rough idling, misfires, or increased fuel consumption. Likewise, the air filter is critical—it prevents debris from entering the combustion chamber and must be checked frequently, especially in the dust-prone roads of Columbia, SC.

Other must-know parts include the glow plugs (essential for cold-starts), the fuel and oil filters, turbochargers, and electronic control modules that monitor everything from fault codes to real-time engine performance. Being able to pinpoint malfunctions in these parts allows for rapid troubleshooting and reduces downtime. With each component interconnected—such as how faulty injectors can lead to low compression or how a weak battery can disrupt the entire starting sequence—being informed is your best defense against unexpected breakdowns.

Common Diesel Engine Troubleshooting Problems in Columbia, SC

Fuel Consumption Issues in Diesel Engine Troubleshooting

Unexpected surges in fuel consumption stand out as some of the most frequent diesel engine troubleshooting challenges for truck owners. When your diesel engines suddenly burn more fuel than usual, it’s often a sign of deeper issues such as a clogged air filter, injector malfunction, or fuel delivery system problem. In Columbia, SC’s humid climate, moisture can accumulate in filters, amplifying clogging risks. Increased fuel consumption isn’t just costly—it’s also an early alert to examine your injectors, air intake, and exhaust for performance and efficiency losses.

Neglecting these warning signs may lead to other common problems, including low engine power, rough idling, or even complete engine failure. A swift visual inspection and employing a diagnostic tool such as an OBD (on-board diagnostics) scanner can reveal specific issues, from fault codes signaling injector faults to signs of electronic control module lag. Taking action at the first sign of high fuel usage will extend the lifespan of your engine and keep your truck confidently rolling through South Carolina’s bustling highways.

Recognizing Engine Fault Codes for Diesel Engine Troubleshooting

Modern trucks rely heavily on integrated sensors and electronic control modules to monitor engine performance and flag any developing issues. Recognizing and interpreting engine fault codes is a vital step in diesel engine troubleshooting. Whether you’re dealing with glow plug failures, injector issues, or sensor malfunctions, your truck’s computer system is designed to alert you before a minor glitch escalates. For Columbia, SC truck owners, understanding how to read these codes—and what common problems they reference, such as a fuel delivery issue or a faulty injector—can save both time and money.

When a warning light appears, plug in a diagnostic tool to access these fault codes. Common codes may indicate a clogged fuel or air filter, air leak, electronic control module issue, or low oil pressure. Resolving these promptly ensures that your diesel engine remains efficient, powerful, and less prone to unexpected breakdowns. Always address codes related to critical functions—especially those involving fuel system delivery or engine overheating—to avoid extensive repairs later on.

- Glow plug failures

- Injector problems

- Clogged filters

- Sensor malfunctions

Step-by-Step Diesel Engine Troubleshooting Guide

- Assess Visual & Audible Symptoms

- Connect Diagnostic Tools to Detect Fault Codes

- Inspect Diesel Engine Fuel System

- Examine Electrical and Glow Plug Systems

- Address Common Problems with Diesel Engines

- Perform Final Checks

| Problem | Possible Cause | Troubleshooting Step |

|---|---|---|

| Hard Starting | Weak battery, glow plug | Check battery, replace glow plug |

| Excessive Smoke | Faulty injector | Inspect & clean/replacement |

| High Fuel Consumption | Clogged filter | Replace filter |

| Engine Knocking | Poor quality fuel | Drain & refill with premium diesel |

Diesel Engine Troubleshooting for Fuel System Problems

Identifying Air and Water Contamination in Diesel Engines

One of the stealthiest enemies in diesel engine troubleshooting is air and water contamination within the fuel system. Even minor amounts of air or moisture introduced through poorly sealed fuel lines or leaky injectors can severely compromise your truck’s performance. These contaminants can cause hard starting, stalling, low engine power, and corrosion in critical internal parts such as fuel injectors and control modules. In Columbia, SC, where seasonal humidity and rainfall are common, diligent inspection for condensation and leaks is vital.

To spot contamination, look for bubbles in fuel lines, milky residues in filters, or persistent water-in-fuel warning lights. Addressing these issues typically involves draining the fuel system, replacing filters, and ensuring all connections are secure. Regularly check the fuel and water separators on your truck, especially before long hauls, to guarantee peak performance and protect engine longevity during diesel engine troubleshooting processes.

How to Fix Clogged Fuel Filters and Lines in Diesel Engine Troubleshooting

Clogged fuel filters and lines are among the top culprits behind sudden loss of engine performance and increased fuel consumption. Dirt, debris, and even microbial growth in stored diesel fuel can quickly obstruct these critical flow pathways. To fix this, begin with a thorough inspection of fuel filters—look for discoloration, sediment buildup, and cracks in the filter body. If your engine is sluggish or stalls under acceleration, chances are a clogged filter or line is to blame.

Replacing a diesel fuel filter is a straightforward DIY task that pays big dividends. Simply relieve fuel pressure, remove the old filter, and replace it with a quality new one—making sure to prime the system for a smooth start. For Columbia, SC truck owners navigating dusty or humid routes, more frequent filter changes can dramatically cut engine troubleshooting incidents and maintain consistent fuel delivery to injectors and cylinder heads.

Diesel Engine Troubleshooting for Electrical & Turbo Issues

Diagnosing Starter and Battery Problems in Diesel Engines

Your diesel engine’s electrical system is the unsung hero of every successful start. Weak batteries, corroded terminals, or malfunctioning starters top the list of electrical problems in diesel engine troubleshooting. If you hear a clicking sound, experience slow cranking, or notice dim dashboard lights, suspect a weak battery or voltage drop. These issues are especially pronounced after extended periods of high humidity that can accelerate corrosion, as often seen in Columbia, SC trucks.

Use a multimeter to test battery voltage (a healthy diesel battery should read around 12. 6 volts when fully charged). Next, check connections for tightness and cleanliness. Starter issues may require professional diagnostics—but ruling out obvious battery faults first can save time and expenses. Consistent electrical checks will keep your engine’s glow plugs, modules, and sensors operating in harmony, minimizing future troubleshooting headaches.

Early Warning Signs of Turbo Failure in Diesel Engine Troubleshooting

The turbocharger delivers the extra power diesel engines need to haul heavy loads reliably. However, any sign of turbo trouble warrants immediate attention. Early warning signs include a loss of engine power, high-pitched whistling sounds, excessive black or blue smoke, and unexplained oil leaks. In Columbia, SC’s heat and varied driving conditions, turbos can be strained by frequent stop-start cycles or insufficient lubrication due to low oil levels or faulty seals.

Regularly examining your turbo for worn seals, shaft play, or oil seepage helps detect problems before catastrophic turbo failure. If any warning signs appear, refrain from continued operation until repairs are made—a failing turbo can rapidly escalate from a minor fault code to a full engine teardown.

“A failing turbocharger can dramatically reduce your diesel engine’s performance — pay attention to whistle sounds, power drops, and oil smoke,” says John, a Columbia-based diesel mechanic.

Preventive Maintenance for Diesel Engine Troubleshooting

Routine Checks and Schedules for Diesel Engines

Preventing the need for emergency diesel engine troubleshooting starts with religiously following routine maintenance schedules. This includes frequent oil changes, air and fuel filter replacements, coolant level inspections, and belt tension checks. For Columbia, SC truck owners, it’s also wise to check the fuel and water separators every week, given the humid local climate. Adhering to a robust maintenance routine not only preserves peak engine performance but also cuts the risk of common problems such as clogged airflow or worn piston rings.

Maintaining a detailed service log is invaluable—noting the dates and types of preventive care carried out allows you to spot emerging patterns, such as repeated injector issues or abnormal fuel consumption. This proactive strategy helps you catch issues early and keeps potential failures at bay.

How Columbia, SC Climate Impacts Diesel Engine Troubleshooting

The challenging weather patterns in Columbia, SC—ranging from humid summer days to surprise downpours—put extra stress on diesel engines. Moisture in the air can lead to fuel and water contamination issues, while the heat accelerates evaporation and wear on rubber seals and gaskets. These climate factors heighten the importance of diesel engine troubleshooting tailored to local conditions.

Truck owners should invest in high-quality filters and check for condensation more frequently, especially during humid spells. Performing a walkaround check after heavy rains or before long drives protects against premature engine wear and helps identify low oil, coolant leaks, or air filter clogs before they compromise your engine’s integrity.

People Also Ask: Answering Your Diesel Engine Troubleshooting Questions

What is the most common problem with diesel engines?

The most common problem with diesel engines is fuel system contamination—either through clogged filters, dirty injectors, or water in the fuel. These issues disrupt fuel delivery, cause rough starting, and degrade engine performance. Early detection through regular filter checks and using clean, high-quality diesel can help Columbia, SC truck owners avoid expensive repairs and keep their engines running smoothly.

What are the first signs of turbo failure in diesel?

Early signs of turbo failure include unusual high-pitched whistle noises, noticeable power loss, blue or black smoke from the exhaust, and visible oil leaks near the turbocharger. If these symptoms arise, you should reduce engine load and schedule a professional inspection. Ignoring early turbo issues can quickly escalate to total turbocharger failure and severe engine damage.

Why is my diesel engine turning over but not starting?

If your diesel engine turns over but fails to start, common culprits include weak batteries, faulty glow plugs, lack of fuel due to clogged filters or delivery issues, and crank sensor malfunctions. In Columbia’s hot climate, fuel evaporation or air locks can also interfere with starting. Diagnose with a visual inspection and use of fault code readers for precise problem identification.

What are the top 5 signs of engine trouble?

The top five signs of engine trouble are:

- Hard or slow starting

- Excessive exhaust smoke

- Abnormal engine noises or knocking

- Rapidly increasing fuel consumption

- Frequent or persistent engine warning lights

Noticing any of these symptoms should prompt immediate diesel engine troubleshooting to prevent costlier damage.

Essential Diesel Engine Troubleshooting FAQs

- How often should I check my diesel engine for issues?

- Which parts are most prone to failure in diesel engines?

- Can I perform basic diesel engine troubleshooting myself?

- When should I seek a professional in Columbia, SC?

| Task | DIY Ability | Professional Need |

|---|---|---|

| Replace fuel filter | High | Low |

| Diagnose fault codes | Medium | Medium |

| Turbo repair | Low | High |

Key Takeaways for Diesel Engine Troubleshooting

- Diesel engine troubleshooting saves money and downtime

- Regular checks prevent major issues

- Columbia, SC drivers face unique climate challenges

- Professional help is just a call away

Ready for Expert Diesel Engine Troubleshooting? Contact Local Diesel Mechanics Today

Resolve engine problems fast—schedule service with trusted Diesel Mechanics.

If you’re ready to take your truck’s reliability to the next level, consider the benefits of a full-service approach to diesel maintenance. By partnering with a dedicated diesel truck repair and service provider, you gain access to advanced diagnostics, preventive care, and expert repairs tailored to the unique demands of Columbia, SC roads. This strategic investment not only minimizes unexpected breakdowns but also extends the life of your engine and maximizes uptime. Explore how a comprehensive service plan can transform your diesel ownership experience and keep your truck performing at its best, mile after mile.

Sources

- https://www.trucktrend.com/how-to/engine-troubleshooting-basics-diesel/ – TruckTrend

- https://www.napaonline.com/en/know-how/diagnosing-common-diesel-engine-problems/ – NAPA Know How Blog

- https://www.popularmechanics.com/cars/how-to/a3566/4296843/ – Popular Mechanics

Understanding diesel engine troubleshooting is crucial for maintaining your vehicle’s performance and longevity. To deepen your knowledge, consider exploring the following resources: “Troubleshooting Common Diesel Engine Issues”: This article provides insights into prevalent diesel engine problems, such as fuel contamination and turbocharger issues, along with preventive measures to keep your engine running smoothly. (middletonmeads. com) “Diagnose Your Diesel Engine Problems”: This resource offers a comprehensive diagnostic tool to help identify and resolve various diesel engine issues, empowering you to address problems efficiently. (hotshotsecret. com) By consulting these resources, you’ll gain valuable insights into diesel engine troubleshooting, enabling you to maintain optimal performance and prevent potential issues.