Common Diesel Engine Problems You Can Fix Today

Did you know: Nearly 60% of diesel truck breakdowns are caused by overlooked engine issues that most owners could fix or prevent? If you drive a diesel in Columbia, SC, knowing which common diesel engine problems to watch for—and how to tackle them—could save you thousands in repairs and keep your truck on the road. Whether you’re a hands-on DIY diesel owner or just looking to understand your engine better, this guide gives you practical steps to fix what’s under the hood today.

Startling Facts: The Hidden Costs of Common Diesel Engine Problems

- Recent studies show nearly 60% of breakdowns in diesel trucks are caused by overlooked common diesel engine problems. Learn how these issues affect reliability and repair costs in Columbia, SC.

The costs of ignoring routine maintenance for diesel engines can escalate quickly. Neglecting small symptoms often leads to massive repairs—think blown head gaskets or failed fuel injectors—that not only cost more but could take your truck off the road for weeks. With high local humidity and temperature swings in Columbia, SC, these risks are even higher due to increased fuel contamination and cooling system stress. Proactive attention to common issues helps truck owners save money and avoid disruptions to their business or daily life.

Diesel engines are known for their reliability, but that dependability hinges on keeping key systems—like the fuel filter, injectors, and coolant—in check. Overlooked problems like an oil leak or clogged air filter not only degrade performance but can cut engine life short. Addressing these common diesel engine problems early is a smart investment that pays off for both older and modern diesel trucks in Columbia, SC.

What You’ll Learn About Common Diesel Engine Problems

- The most frequent diesel engine issues truck owners face

- How to troubleshoot and fix common diesel engine problems

- Preventive maintenance tips for diesel engines

- When to seek a professional diesel mechanic in Columbia, SC

This comprehensive guide will empower you to recognize, troubleshoot, and fix many common diesel engine problems yourself—while knowing when to call a pro. You’ll discover what issues to watch out for, how to check vital components like the fuel system and cooling system, and practical strategies tailored to our regional challenges in Columbia, SC.

Miss a scheduled oil change or ignore that plume of blue smoke, and you could be facing major downtime. But with regular fuel filter replacement, smart diagnostics, and early action, you can avoid costly repairs. Read on to get key insights that every diesel truck owner in Columbia, SC needs to stay ahead of engine problems and keep trucks running strong.

For truck owners who want to go beyond the basics, understanding the full range of diesel truck repair and service options available in Columbia, SC can make a significant difference in both troubleshooting and long-term reliability. Exploring professional resources ensures you’re prepared for issues that require more than just DIY fixes.

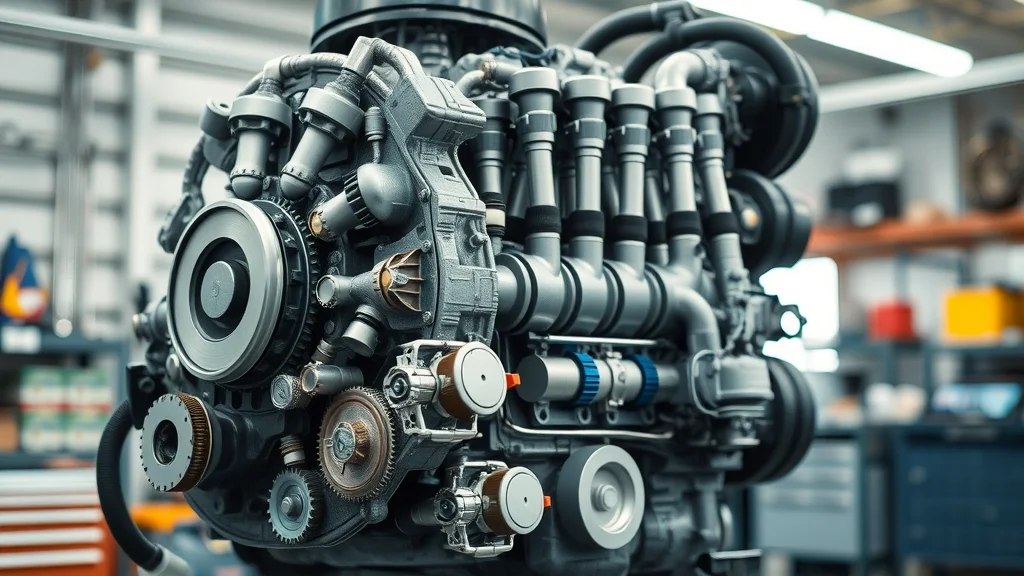

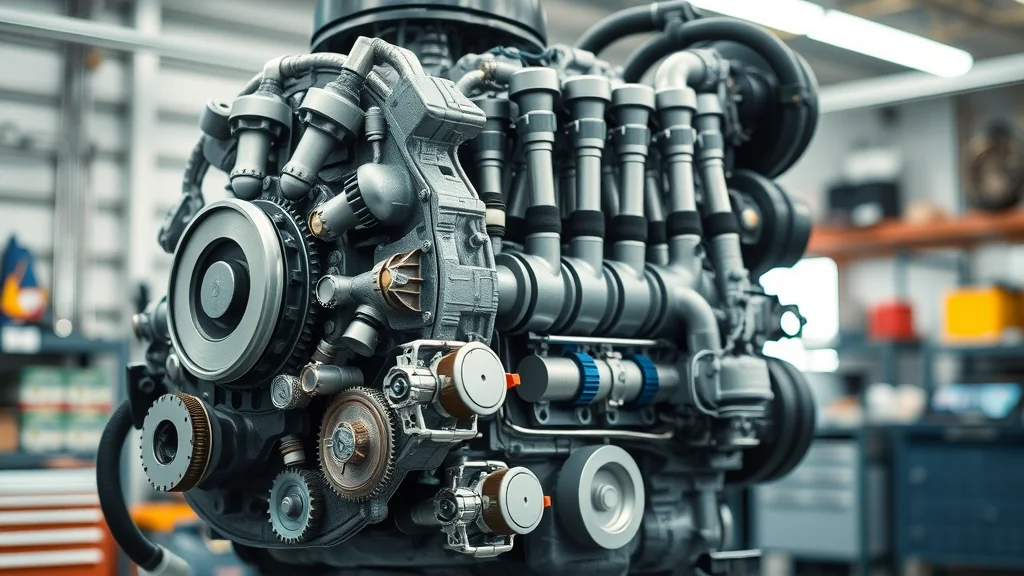

Understanding Diesel Engine Basics for Truck Owners

How Diesel Engines Work and Why Their Problems Matter

- Key differences between diesel engines and gasoline engines

- Why common diesel engine problems need prompt attention

Diesel engines power trucks with reliable, high-torque output and superior fuel economy compared to gasoline engines. They differ from gas motors by using compression ignition—fuel is injected directly into high-pressure air in the cylinder head and spontaneously combusts, driving the pistons. Their heavy-duty design lets them handle more miles, but also means precise fuel system components—like fuel injectors and glow plugs—are crucial for performance.

Because diesel engines rely so much on properly timed fuel injection and high-pressure systems, issues like clogged fuel filters or contaminated fuel quickly spiral into larger problems, from rough idling to catastrophic failures. Neglecting warning signs in diesel engines can lead to breakdowns that are much costlier and more disruptive than those typically seen with gasoline motors. That’s why staying attuned to common diesel engine problems, especially in tough South Carolina conditions, is key.

10 Most Common Diesel Engine Problems Truck Owners Face

- Hard starting or failure to start

- Excessive smoke from the exhaust

- Loss of power or sluggish acceleration

- Overheating

- Knocking noises

- Poor fuel efficiency

- Unusual engine vibrations

- Check engine light warnings

- Oil or coolant leaks

- Frequent stalling

According to diesel mechanics in Columbia, SC: “Ignoring small engine issues today can lead to costly major repairs tomorrow.”

| Common Diesel Engine Problems | Symptoms | Potential Cause | Quick Fix |

|---|---|---|---|

| Hard starting | Engine cranks but won’t fire up | Weak battery, faulty starter, or bad glow plugs | Test battery and starter, replace glow plugs |

| Excessive smoke | Black, blue, or white smoke from exhaust | Fuel injector, air filter, or head gasket issues | Replace air filter, check injectors, seek professional help |

| Loss of power | Sluggish acceleration, poor response | Clogged air or fuel filter, turbo or injector problems | Replace filters, inspect turbo and injectors |

| Overheating | Temperature gauge high, steam or coolant loss | Low coolant, faulty radiator or water pump | Top up coolant, inspect radiator & water pump |

| Knocking noises | Sharp, metallic engine sounds | Injector timing, low-quality diesel fuel | Check timing, use quality fuel, clean injectors |

| Poor fuel efficiency | Increased fuel consumption | Dirty air/fuel filters, EGR valve issues | Replace filters, clean or replace EGR valve |

| Oil or coolant leaks | Spots under truck, low oil/coolant levels | Head gasket or seal failure | Inspect and replace gaskets or seals |

Diesel Engine Not Starting: Diagnosing the Root Cause

Battery, Starter, and Glow Plug Checks

Hard starting is one of the most widespread common diesel engine problems for truck owners. If your engine cranks slowly or refuses to start, begin with a thorough battery assessment—check for strong voltage and clean, corrosion-free terminals. Diesel engines demand higher cranking amps, especially in colder weather, which puts extra stress on batteries and starters. If the battery checks out, move to the starter. Listen for a clicking noise (indicates a bad solenoid) or total silence (possible starter failure).

Don’t overlook glow plugs: These heat up combustion chambers for a proper air-fuel mixture ignition, especially on chilly Columbia, SC mornings. Faulty glow plugs—or a malfunctioning relay—means the engine won’t get hot enough to start cleanly. Use a multimeter to check their resistance, replacing any that are outside the correct range. Ruling out these basic components first saves time (and money) before digging into deeper fuel system problems.

Fuel System and Fuel Injector Problems

- Importance of a clean fuel filter in diesel engine performance

- Diesel fuel contamination issues in Columbia, SC

Even with perfect battery and starter health, a diesel engine can’t fire if fuel isn’t reaching the cylinders in the right quantity and quality. Clogged or dirty fuel filters are among the leading causes of starting trouble. These filters trap debris and water from the fuel tank, but when full, they choke off the fuel supply, resulting in hard starts or no start at all. Always use a clean fuel filter—swap it out every 10,000 to 15,000 miles or sooner if you regularly fill up at smaller stations, which are more prone to contaminated fuel.

On top of filtration, inspect the fuel injector system. Modern diesels use high-pressure injectors to atomize diesel fuel perfectly; if these get clogged or leak, starting and running problems follow. Use diesel additives periodically and have injectors professionally cleaned or replaced when needed. With South Carolina’s humid weather, extra attention is needed to keep water and bacteria from creating fuel contamination.

Excessive Smoke: Color Meanings and Solutions for Diesel Engines

Black, Blue, and White Smoke Explained

Observing unusual exhaust smoke is a sure sign of engine issues. Each smoke color points to a specific common problem in diesel engines. Black smoke indicates unburnt fuel, commonly due to restricted air filter, bad fuel injectors, or excessive fuel delivery. Blue smoke signals burning oil, suggesting piston ring wear or valve seal leaks. White smoke often means coolant or fuel isn’t burning correctly—potentially due to injector timing issues or a failing head gasket.

To address black smoke, check that your air filter isn’t blocked—replace it if dirty. Persistent blue smoke requires a deeper dive into oil seals or rings, while ongoing white smoke demands urgent attention, as it could indicate a coolant leak into the combustion chamber. Diagnosing the correct smoke color helps prevent small fixes from turning into engine rebuilds.

When Smoke Indicates Common Diesel Engine Problems

- Role of air filter and fuel contamination in exhaust smoke

- Signs of failing head gasket

- When to consult diesel mechanics

If you notice thick, dark smoke, start by checking and replacing air and fuel filters. Excess smoke tied to fuel issues can often be traced to using contaminated fuel or worn-out injectors. For blue smoke, inspect for oil leaks or signs of oil consumption (oil leaks on the ground or on the engine block). White smoke, particularly if sweet-smelling or persistent, can point to a cracked head gasket—one of the most serious common diesel engine problems. Coolant in the oil or exceptionally high coolant loss are major red flags; it’s time to call a certified diesel mechanic near Columbia, SC.

Loss of Power and Poor Acceleration: Key Diesel Engine Issues

Turbo, Fuel Injectors, and Air Intake Diagnostics

- Common causes for loss of power in diesel engines

- Troubleshooting clogged air filters and faulty fuel injectors

Few things are more frustrating than pressing the accelerator—and your diesel truck barely responds. Two of the most frequent causes are clogged air filters (restricting air intake) and gummed-up fuel injectors. Both problems rob your engine of the precise air-fuel mixture needed for proper combustion, leading to decreased engine performance and increased fuel consumption. In turbocharged engines, a leaking boost pipe or faulty turbo can also result in poor acceleration and low power delivery.

To restore power, start by swapping the air filter—a simple and affordable fix. If power loss persists, run fuel system cleaners through your fuel injectors, or have them tested by a professional diesel mechanic. Don’t forget to inspect hoses and the particulate filter for blockages or restrictions.

Overheating in Diesel Engines: How to Prevent and Fix It

Cooling System Maintenance and Checks

- Importance of radiator, coolant levels, and head gasket in engine performance

- Columbia SC climate challenges for diesel cooling systems

The heat and humidity in Columbia, SC, place additional strain on cooling systems, making overheating a far more common issue for local diesel owners. An overheating engine risks catastrophic damage: warped cylinder heads, popped head gaskets, and worst-case, a seized engine. Common causes include a clogged radiator, low coolant, faulty water pump, or a failing radiator cap—each reducing cooling efficiency.

Regularly check and top up coolant levels. Flush the radiator according to manufacturer guidelines, and inspect for leaks or worn coolant hoses. If you notice the temperature gauge spiking or see steam from the hood, don’t ignore it. Overheating can quickly destroy an otherwise-reliable engine, so a proactive stance with maintenance prevents the majority of these common diesel engine problems.

Diesel Engine Knocking Noises: Diagnosing and Repairing

Fuel Injector Problems and Timing Issues

- How incorrect timing or clogged fuel injectors can cause engine knocking

Knocking or pinging sounds are an important warning that your diesel engine needs attention. These noises typically indicate fuel is combusting at the wrong time or in the wrong manner. Clogged or worn fuel injectors can drip or misfire, dumping excess fuel that combusts too late or too early. The most severe cases trace back to incorrect injection timing, which can damage pistons, cylinder walls, or even the crankshaft over time.

To fix knocking, inspect and clean or replace your injectors regularly, especially if your truck has experienced contaminated fuel. If replacing injectors doesn’t fix the issue, have a mechanic check the engine’s timing with the right diagnostic tools. Catching and correcting knocking noises early prevents more expensive repairs down the line.

Dealing with Oil and Coolant Leaks in Diesel Engines

Head Gasket and Seals: Inspection Tips

- Identifying signs of major leaks and when head gasket replacement is needed

Oil and coolant leaks are easy to miss at first—but letting them go leads to lower engine performance, overheating, and sometimes total engine failure. Common visible signs include oil stains on your driveway or low levels of coolant in the reservoir. In diesel engines, leaks often point to worn gaskets or seals, especially the head gasket, valve cover, or oil pan seals. A leaking head gasket can also let coolant mix with engine oil, causing a milky residue on the dipstick or under the oil cap.

If you spot a fresh oil leak under your truck, trace its source. Sometimes, tightening bolts or replacing a simple gasket is a quick fix. For recurring or severe leaks—with coolant loss or engine overheating—seek a professional for a proper head gasket inspection and possible replacement. Acting early keeps critical fluids in and contaminants out, preventing one of the more catastrophic common diesel engine problems.

Preventive Maintenance for Common Diesel Engine Problems

- Regular oil changes and filter checks

- Inspecting and replacing air and fuel filters

- Fuel system and cooling system best practices

The single best way to avoid common diesel engine problems is a solid routine of preventive maintenance. Change oil and filters as scheduled—dirty oil accelerates engine wear, while clogged air and fuel filters cut performance and fuel economy. Regularly inspect the cooling system (radiator, coolant, water pump, hoses) and look for any early signs of leaks. Check fuel system components, including using only high-quality diesel and draining water separators to avoid contaminated fuel.

Make a habit of monthly engine bay inspections. Listen for odd noises, look for smoke colors, and use diagnostic tools if your check engine light flashes. The time you spend now is a tiny investment compared to the cost of major engine overhauls later. Routine care keeps modern and older diesel engines running at their best, even under the tough conditions often encountered around Columbia, SC.

Columbia, SC Diesel Truck Owner Insights

Local diesel expert: “Our climate increases the risk of overheating and fuel contamination in diesel trucks.”

- Regional tips for diesel engine longevity

- Why local knowledge matters

Diesel trucks in Columbia, SC face unique challenges, from sweltering summers that stress cooling systems to humidity that boosts fuel contamination risks. Local mechanics recommend more frequent coolant and filter checks, using fuel additives that inhibit microbial growth, and parking in the shade whenever possible. Trusting a local expert with Columbia-specific experience helps spot emerging problems before they become breakdowns, making all the difference for both work and personal diesel trucks.

Rely on neighborhood diesel mechanics who understand our region’s quirks. They often see patterns—seasonal spikes in overheating, or clusters of injectors clogged by bad diesel fuel—that out-of-town or general auto shops may miss. Columbia diesel owners who stay ahead of maintenance protect their investment and stay on the road longer.

Top Tools and Resources for DIY Diesel Engine Repair

- Essential tools for addressing common diesel engine problems

- Online resources and manuals

Ready to handle basic repairs or troubleshooting yourself? A few essential tools will make your diesel maintenance much easier. At minimum, invest in a quality socket and wrench set, multimeter, oil filter wrench, fuel filter pliers, and a diesel-rated code scanner. Keep spare filters, engine oil, and coolant on hand. For most modern diesel engines, a laptop or tablet with an OBD-II diagnostic tool grants valuable real-time data for fast issue detection.

For more guidance, tap into reputable online resources: Your truck’s official service manual, trusted YouTube diesel repair channels, and community forums tailored to your model. Always refer to step-by-step guides designed for diesel engines and, when in doubt, consult a professional. The right knowledge and equipment help keep common diesel engine problems from becoming major headaches.

People Also Ask: Diesel Engines and Common Issues

What is the major problem in a diesel engine?

Answer: The most major problem in a diesel engine is usually related to fuel system failures, especially clogged fuel filters and faulty injectors.

What’s the worst thing for a diesel engine?

Answer: Contaminated diesel fuel is one of the worst things that can happen to a diesel engine, as it leads to injector, pump, and engine damage.

What is the most unreliable diesel engine?

Answer: Reliability can vary, but some poorly-designed or outdated diesel engines suffer known weaknesses; Ford’s 6.0L Powerstroke is commonly cited.

What is the holy grail of diesel engines?

Answer: Many consider the Cummins 5.9L 12-valve as the ‘holy grail’ for its legendary durability and ease of repair.

Key Takeaways for Diesel Truck Owners

- Act promptly on common diesel engine problems

- Regular inspections prevent major issues

- Seek certified diesel mechanics for complex engine repairs

Quick action and routine checks can stop minor issues from ballooning into major repairs. Never hesitate to seek help from certified pros for anything you aren’t sure about, and keep consistent records of your maintenance efforts for the best results.

Frequently Asked Questions About Common Diesel Engine Problems

- What causes poor diesel engine performance? Often it’s restricted air or fuel flow from clogged filters, dirty injectors, or a failing EGR valve. Bad fuel or leaks can also reduce engine performance.

- How often should I change diesel engine oil and filters? Stick to the manufacturer’s recommendations—usually every 5,000 to 10,000 miles—or more frequently in tough conditions like those in Columbia, SC.

- Can I prevent all common diesel engine problems with maintenance? Routine maintenance prevents most—but not all—issues. Some problems stem from defective parts or unavoidable wear, but catching them early saves money.

- Is professional help always necessary? Many basic issues (filters, batteries, minor leaks) can be fixed DIY. Seek professional help for anything involving major engine disassembly, persistent leaks, or computer diagnostics.

Final Thoughts: Stay Ahead of Common Diesel Engine Problems

- Emphasize prevention, regular servicing, and awareness of common diesel engine problems to extend vehicle life in Columbia, SC

Commit to prevention and regular checks, and you’ll avoid most common diesel engine problems, keeping your Columbia truck dependable for years to come.

If you’re ready to take your diesel truck care to the next level, consider exploring the full spectrum of diesel truck repair and service solutions available from trusted professionals in Columbia, SC. Whether you’re seeking advanced diagnostics, comprehensive maintenance plans, or expert advice tailored to your vehicle’s needs, partnering with a dedicated service provider can help you maximize uptime and protect your investment. Dive deeper into specialized support and discover how a proactive approach can keep your diesel engine running stronger, longer—no matter what the road throws your way.

Looking for Expert Help? Trust the Diesel Mechanics at Road1 Columbia, SC

- Contact the professionals for comprehensive diesel engine diagnostics, repair, and maintenance: Diesel Mechanics

Sources

- https://www.yourmechanic.com – The Most Common Diesel Engine Problems

- https://itstillruns.com – Common Problems With Diesel Engines

- https://www.dieselhub.com – 6.0L Powerstroke Problems

- https://www.truckpaper.com – Truck Service Tips: Common Engine Problems

- https://www.agriculture.com – 5 Most Common Diesel Engine Problems

To enhance your understanding of common diesel engine problems and their solutions, consider exploring the following resources: “Top 5 Common Diesel Engine Problems and How to Avoid Them”: This article provides insights into prevalent diesel engine issues, including fuel contamination and injector problems, along with preventive measures to maintain engine health. (stevensdiesel. com) “6 Common Problems with Diesel Engines”: This resource outlines typical diesel engine challenges such as hard starting and black exhaust, offering practical advice on early detection and resolution. (gotodobbs. com) By delving into these articles, you’ll gain valuable knowledge to proactively address and prevent common diesel engine issues, ensuring your vehicle remains reliable and efficient.